Everything You Need To Know About NEMA Connector: Feature, Type, And Mechanism

Electrical and electronic appliances play an intricate role in the daily life of everyone in today's society. There's barely any sphere of modern living that the technology and advances in electrical engineering haven’t touched in one way or the other.

Printed circuit boards, solid-state construction, microchip technology, and other advances have rendered electronic components such as cords, extensions, and connectors safer and more durable. However, it's crucial to remember that electronics are still prone to damage and failure, particularly if you don't know the types, features, and mechanisms involved in the connectors you're dealing with.

Equally vital, end-users need to learn these details since the NEMA standard involves various connectors and configurations. This article summarizes NEMA connectors and various details about the plugs or receptacles currently in use.

What is a NEMA Connector?

NEMA connector is a method used for establishing a connection between an electronics gadget and a power outlet. These connectors can conduct direct current (DC) or alternating current (AC). Most homes, buildings, stores, and offices have AC. However, components like batteries have DC.

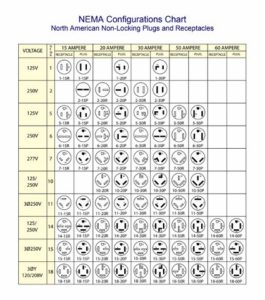

Even if most people are used to three or two-pronged connectors usually found at home, there are several hundred other connectors in the electrical industry worldwide. They vary according to their voltage and amperage. Currently, NEMA connectors in the United States have amperages ranging from 15 to 60 amps (A) and voltages rating between 125 to 600 volts (V).

Connectors, outlets, and plugs exist with different configurations and have varying blade shapes, measures, widths, positions, and forms. These differences mean that you can't interchange them, or you need to use the correct plugs for suitable connectors. Hence, combining the right voltage, grounding, and current capacity is a major safety concern.

NEMA Standard

Every manufacturer of electronic components and devices in the US has to comply with the standards set by NEMA. This helps produce consistency in electrical connectors across the entire industry. Through NEMA standardization, manufacturers and end-users can identify the various pin positions of receptacles and plugs depending on their voltage and amperage.

As illustrated in the chart below, NEMA 2-50, NEMA 6-50, and NEMA 24-15 have one thing in common. Each one of them has a unique pin configuration and positioning. The difference widens when considering the voltage and amperage, with 2-20 and 6-50 having 250V and 24-15 at 347V.

NEMA Receptacles, Plugs, and Power Cords

As previously mentioned, electrical connectors, receptacles, and plugs in the US meet the quality standards of NEMA. The two most widely used connectors are NEMA 1015P and NEMA 5-15P. These two connectors have steel or brass prongs coated with tin, nickel, or zinc embedded in molded rubber bodies.

Other connector types have higher voltages and different prong placements. The placement and configuration of the prongs and receptacles can make the connector a locking or non-locking type. As you would imagine, these two types have different uses and serve specific purposes, some in industrial settings.

Types of NEMA Connectors And Mechanisms

The two main categories of NEMA connectors are locking and non-locking. Let's take a close look at each of these types and their unique uses.

Locking

Locking NEMA connectors have curved blades, which you have to turn upon insertion into their receptacle to lock in place. This prevents the connections from getting disconnected or dislodged accidentally. Most locking connectors are meant for industrial and commercial use. However, you can also find midget or miniature locking connectors, typically identified by "ML." They become helpful in places where their larger counterparts won't fit. There are three varieties of these connectors, namely:

- Two-pole, grounded, 125V rating

- Two-pole, ungrounded, 125V rating

- Three-pole, ungrounded, 125/250 V rating

The industry uses "L" placed in front of the series number to distinguish locking connectors from other non-locking NEMA connectors. For example, NEMA L6 or NEMA L7.

- NEMA L1 - NEMA L1 has a single-pole, neutral, and two wires, meaning it's ungrounded with a 125V single phase. They are built for 15mp appliances.

- NEMA L2 - NEMA L2 has a two-pole, two-wire, single-phase, ungrounded with a 250V rating made for 20-amp devices.

Non-Locking

Non-locking NEMA connectors, as the name implies, have no locking mechanism between the prongs and receptacles. NEMA 1 and NEMA 5 are the most widely used in the United States among these connectors. You can find them with two plugs without a ground or two prongs with a ground. Over the past couple of years, constructors were required to install receptacles that have NEMA 5 ground plugs. Consequently, the NEMA 1 connector is gradually phasing out of use.

According to the NEMA standardization, the first number indicates the plug configuration. This includes voltage, wires, and several prongs. The grounding type can either be two, three, or four poles, and more.

The second number is the code that denotes the amp rating, and it is either followed by an "R" or "P," which are receptacle and plug. For instance, NEMA 5-15R is a 125V, three-wire, and two-pole receptacle with a rating of 15 amps. Some types of this connector include NEMA 1, 2, 3, etc.

Final Words

There you go, the different types, features, and mechanisms of NEMA connectors. These details can get confusing even for the pros. So, refer to the illustration and leave us a comment in case of any questions.